Dyna-Slide Gentle Handling Magnet Feeders

When it comes to gentle handling vibratory parts feeders, Dyna-Slide delivers! If we can feed light bulbs without damaging the parts, we can feed magnet blanks. The system shown in the video below feeds and orients magnets standing on end and then feeds them past a vision system camera to determine right-side-up orientation. Magnets are then ‘flipped’ one way or the other by an air knife and then collected into a single line stream of properly oriented parts. Those right-side-up parts are then distributed to two output lanes that each feed 60 parts per minute to customer’s downline tooling.

Dyna-Slide Vibratory Feeder for Magnets

Please contact us today at cdsmfg@netacc.net to discuss your requirement, and be sure to visit Dyna-Slide Gentle Feeders for Delicate Parts for more info about CDS Lipe’s line of Dyna-Slide gentle vibratory parts feeders.

Medical Parts Sorting Services

CDS LIPE Manufacturing provides automatic sorting of medical parts. Automatic sorting machinery including precision roll sorters, digital micrometer length and diameter sorting systems, vision systems and more, currently on our production floor allows us to sort for diameter, length, missing threads, chips in the ID, and much more.

One such application recently completed required length sorting of a .015″ diameter part for overall length. Parts were sorted using automatic digital micrometer length inspection equipment. We have sorted millions of these parts for this particular customer with no inefficiencies reported.

Check out Parts Sorting Services – CDS Manufacturing for more info, and please contact us at cdsmfg@netacc.net to discuss your application.

We look forward to hearing from you.

_______________________________________________________________________________________

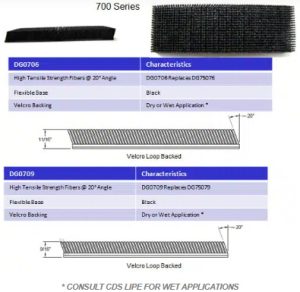

Vibratory feeder brush (vibratory feeder carpet) by DYNA-SLIDE

Dyna-Slide Directional Feeder Brush is available in sizes up to 12″W x 60″L

3M Brushlon, a product of 3M Corporation, has been utilized for vibratory parts feeders, vibratory conveyors, and vibratory accumulators for decades. CDS LIPE Dyna-Slide vibratory parts feeders have used 3M Brushlon with a 20-degree tilt for many years to be gently feed and orient a wide variety of parts without damage. To the surprise of many who relied on 3M Brushlon, the product was discontinued by 3M Corporation around 2020.

With such a high demand for vibratory feeder brush similar to 3M 321B and 331B series

Brushlon, CDS LIPE has developed our own line of vibratory feeder brush mats with a 20-degree fiber tilt and comparable trim lengths. After extensive testing and in consideration of our customer’s expectations, we are pleased to offer DYNA-SLIDE DIRECTIONAL FEEDER

BRUSH as a comparable alternative to 3M Brushlon for your vibratory parts feeding requirements.

Dyna-Slide Directional Feeder Brush is ideal for moving parts, packages or materials quickly, gently and quietly. Its 20 degree fiber on a vibratory surface efficiently feeds, orients, accumulates, transports an extraordinary variety of parts packaged and materials Replaceable, long lasting brush is gentle on fragile parts and part surfaces. Typical Dyna-Slide Brushlon conveyor, feeder or accumulator operate at less than 65 dba. Available for both wet and dry applications. Also know as carpet conveyors and brush conveyors.

Check these videos of vibratory parts feeders, conveyors, and accumulators designed and built by CDS LIPE using directional feeder brush: Gentle Parts Feeders by Dyna-Slide – CDS LIPE (cds-lipe.com)

Please consider DYNA-SLIDE DIRECTIONAL FEEDER BRUSH as a comparable 3M Brushion* replacement for next vibratory parts feeding requirement.

CDS LIPE provides replacement brush for GRACO FLEX FEEDERS as well as other vibratory feeders.

Please visit DYNA-SLIDE Feeder Brush: CDS LIPE’s Parts Handling for more info.

*3M Brushlon is a registered trademark of 3M Corporation

_______________________________________________________________________________________

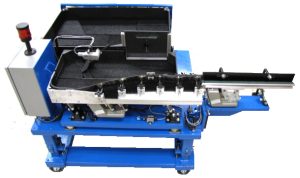

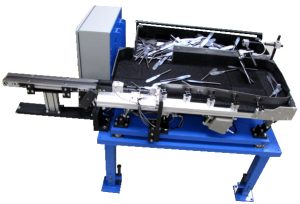

Vision based parts feeder systems by DYNA-SLIDE

CDS LIPE Manufacturing designed and built this gentle handling Dyna-Slide linear vibratory parts feeder to feed and orient sprockets. Vision based sortation equipment is used to detect sprockets with the wrong side up. When a misoriented wrong side up part is detected the vision system, pneumatic tooling flips the sprocket over to a right side up orientation. Properly oriented sprockets are fed in a diameter to diameter specified end up orientation to the customer’s down line equipment.

Please visit Dyna-Slide Gentle Feeders for Delicate Parts for more info.

_______________________________________________________________________________________

Fast, efficient, & flexible grinder feeders by DYNA-SLIDE

This centerless grinder feeder system designed and built by CDS LIPE Manufacturing includes a vibratory pan feeder bulk supply, linear vibratory parts feeder, and vibratory output track. Adjustable fence and wiper tooling allows this feeder system to accommodate a wide variety of rod lengths and diameters. Properly oriented parts are fed to the customer’s centerless grinder infeed.

Please visit CDS LIPE: Automated Grinder Feed Systems for more info.

_______________________________________________________________________________________

DYNA-SLIDE feeders; the gentle handling feeder system of choice

CDS LIPE Manufacturing designed and built this gentle handling Dyna-Slide linear lightbulb feeder system. This system feeds lightbulbs with connecting wires attached to a head hanger track that positions them for removal by customer’s equipment at a rate of 60 ppm. This system feeds lightbulbs with zero damage to the product.

Please visit Dyna-Slide Gentle Feeders for Delicate Parts for more info regarding our gentle parts feeders.

_______________________________________________________________________________________

DYNA-SLIDE centerless grinder feeders

CDS LIPE Manufacturing designed and built this DYNA-SLIDE F1436 linear vibratory parts feeder to feed cylindrical rods of varying lengths and diameters to our customer’s centerless grinder. Adjustable fence and wiper tooling makes changing set ups between parts fast and simple. This automatic grinder feeder delivers parts in an end-to-end orientation to the customers grinder infeed equipment.

Please visit CDS LIPE: Automated Grinder Feed Systems for more info regarding our centerless grinder feed systems.

_______________________________________________________________________________________

Custom bulk supply solutions for your particular requirements

CDS LIPE Manufacturing designed and built this custom bulk handling system. An automatic bin dumper supplies parts to a pan feeder. The pan feeder feeds parts to a hopper elevator which provides a metered flow of product to customer’s equipment.

Please visit CDS LIPE: Automated Bulk Part Supply Equipment Solutions for more info regarding our intelligent bulk supply solutions.

_______________________________________________________________________________________

DYNA-SLIDE vibratory parts feeders gently feed and orient kitchen utensils

This gentle handling vibratory parts feeder designed and built by CDS LIPE Manufacturing feeds and orients knife blade blanks. The operator loads blanks into the on-board zero drop bulk supply section of the DYNA-SLIDE vibratory parts feeder. Custom tooling singlulates knife blade blanks into an end-to-end orientation. Properly oriented parts are fed out the end of the vibratory output track in an end-to-end orientation with the specified end leading.

Please visit Dyna-Slide Gentle Feeders for Delicate Parts for more info regarding our gentle parts feeders.

_______________________________________________________________________________________

Custom parts feeders for hard to handle components.

CDS LIPE Manufacturing designed and built this vibratory parts feeder system to feed and orient universal joints. This system utilizes a bin dumper to supply parts to a vibratory pan feeder (bulk supply). A sensor in the pan feeder automatically monitors and maintains the number of parts in the pan feeder. The vibratory pan feeder (bulk supply) feeds parts to a recirculation tray. The recirculation tray feeds parts to a vibratory orientation track. Equipped with custom tooling, the orientation track diverts misoriented parts back into the recirculation tray. Properly oriented parts are fed to the end of a vibratory output track for removal by pick and place equipment. Upon receipt of a shake hands signal from the customer’s equipment, the pick and place transfers four universal joints to a pick conveyor in an equally spaced configuration for removal by customers robot.

Please visit CDS LIPE: Horizontal Part Feeders & Orientation Solutions for more info regarding our vibratory parts feeders.

_______________________________________________________________________________________

Improve production flow and organization with a custom DYNA-SLIDE accumulation table from CDS LIPE Manufacturing

Custom accumulation tables that are designed to maximize efficiency by keeping the filler running during normal stoppages by adding temporary storage between production machinery. Offering a gentle product handling and relief of back pressure by accepting overflow from the mass conveyors as needed. This is what you need to prevent bottleneck in your production line.

Gentle feeding for parts, packages and materials. These modular systems can be combined with feeding and orientation automation to create a complete system or used as stand-alone bulk part supply. Custom accumulation tables lined with vibratory feeder brush allows for gentle reliable feeding of a wide range of parts. Contact us today for a free quotation.

Please visit CDS LIPE: Custom Accumulation Tables for Automation for more info regarding our accumulation tables.

_______________________________________________________________________________________

Linear vibratory DYNA-SLIDE feeders for gentle parts feeding applications.

CDS LIPE Manufacturing designed and built this custom Dyna-Slide F2148 linear vibratory feeder system. This system automatically feeds and orients cam gears in a diameter-to-diameter x defined face up orientation at a rate of 15 parts per minute.

Please visit Dyna-Slide Gentle Feeders for Delicate Parts for more info regarding our gentle handling vibratory parts feeders.

_______________________________________________________________________________________

Custom gentle vibratory parts feeders by CDS LIPE Manufacturing

CDS LIPE Manufacturing designed and built this gentle handling DYNA-SLIDE F1436 vibratory parts feeder. This system automatically feeds and orients glass disks. The operator loads parts into the bulk supply. The bulk supply feeds parts to the recirculation tray of the feeder. A sensor automatically monitors and maintains the number of parts in the recirculation tray for on-demand feeding from bulk. Parts are fed to an orientation track the diverts misoriented parts back into the recirculation tray. Properly oriented parts are fed to an output chute where they exit the gentle handling parts feeder in a rolling orientation. This system feeds parts at a rate of over 100 parts per minute.

Please visit Dyna-Slide Gentle Feeders for Delicate Parts for more info regarding our gentle handling vibratory parts feeders.

_______________________________________________________________________________________

Intelligent Bulk Supply Systems by CDS LIPE Manufacturing

CDS LIPE Manufacturing designed and built this bulk supply system for a long time repeat customer. This system feeds parts from a bin dumper to a tray feeder. The tray feeder supplies parts to a hopper elevator that delivers parts to the customer’s left side or right side bowl feeder with the aid of a switch gate.

Please visit CDS LIPE: Automated Bulk Part Supply Equipment Solutions for more info regarding our intelligent bulk supply solutions.

_______________________________________________________________________________________

CDS Manufacturing Receives Another Vision Inspection Services Order

CDS Manufacturing has received an order to sort 200,000 sleeves. Using automatic vision inspection equipment currently on our floor, these parts will be sorted for chips in the ID, hole presence, and mixed parts. We have sorted millions of parts without failure on this equipment.

_______________________________________________________________________________________

Popular Ball and Bearing Sorting System

CDS Manufacturing recently completed another precision roll sorter. This system equipped with a bulk dumper, ball feeder, and precision roll sorter assembly with a pair of .000005″ TIR rollers was recently built to sort bearing balls. This system can sort balls at over 24,000 parts per hour into 10 different size categories. This system has proven to be a popular choice among bearing and ball manufacturers. Check out our roll sorter page for more info.

_______________________________________________________________________________________

Vision Inspection Services Save Money and Increase Efficiency

CDS Manufacturing offers inspection and sorting services using a wide array of automatic equipment currently on our production floor. In addition to laser length sorting equipment, laser diameter sorting equipment, and precision roll sorters, we also have high speed vision inspection machinery available for sorting our customers product. Our customers prefer our automatic vision inspection service because it is faster and much more efficient than manual processing by an operator. We have sorted millions of brass inserts for chips in the ID, missing threads, missing countersink, mixed parts, and more with our vision inspection equipment. We would be happy to discuss your application. Call us today for a free analysis and quotation for our automatic vision inspection services.

_______________________________________________________________________________________

O-Ring Installation Equipment In High Demand

A piece of equipment that is gaining popularity is our automatic o-ring installation machinery. These systems are available in modular, semiautomatic, and fully automatic configurations. Our fully automatic systems include vibratory feeders for the o-ring and the receiving part, indexing part nests for synchronous operation, pick and place equipment with custom end tooling for part transfer and o-ring installation, vision inspection equipment to confirm o-ring installation, and good / reject part gating systems to deliver parts to their respective outputs. A system recently designed and built by CDS Manufacturing is shown below. Contact us today for a free expert analysis of your requirement.

_______________________________________________________________________________________

IN HOUSE SORTING SERVICES ON RECORD PACE

CDS Manufacturing provides in house sorting and inspection services. Current equipment on our floor includes diameter inspection machines, length inspection machines, high speed vision systems, precision roll sorters, and more. In the last two months we have sorted over 5,000,000 pins, roller bearings, sleeves, medical components, lightbulb filaments, plastic parts, nuts, and brass inserts using automatic inspection and sorting equipment on our production floor.

CLICK HERE or more information on our sorting and inspection services.

_______________________________________________________________________________________

CDS MANUFACTURING COMPLETES AUTOMATIC BALL BEARING SORTING SYSTEM

CDS Manufacturing has just completed a precision roll sorting system equipped with an automatic ball feeder, a precision roll sorter equipped with a pair of .000005″ TIR rollers.. (YES! That’s FIVE MILLIONTHS of an inch), adjustable height and angle stanchion, roller position adjustments, roller position locks, adjustable fallout baffles, and seven stainless steel strorage bins all mounted on a portable pedestal base.

The operator sets up the precision roll sorter for the desired fallout and then loads parts into the ball bearing feeder. The ball bearing feeder feeds ball bearings to the precision roll sorter. The roller bearings travel down the roll sorter and fall through the rollers at their predetermined locations. Sorted parts are stored in the stainless steel containers below.

_______________________________________________________________________________________

CDS MANUFACTURING RECEIVES SERVICE CONTRACT FOR VISION INSPECTION OF 1 MILLION BRASS INSERTS PER MONTH

CDS Manufacturing has received a service contract to provide automatic vision inspection services at our Rochester NY facility. 1 Million brass inserts per month are automatically inspected using vision inspection equipment on our production floor. Brass inserts are inspected for missing countersink, thread presence, and chips in the inner diameter. This service has prevented hundreds of defects from reaching our customer’s automotive client and resulted in a significant cost savings by avoiding containment. The automatic vision inspection services provided by CDS Manufacturing have effectively added money to our customer’s bottom line.

CLICK HERE to check out a vision inspection system built for one of our past customers:

_______________________________________________________________________________________

CDS MANUFACTURING COMPLETES AUTOMATIC O-RING INSTALLATION MACHINE

CDS Manufacturing has completed a custom designed and built automatic o-ring installation machine. This system automatically feeds and orients draincocks to a pick up nest where a pick and place loads it onto an indexing dial plate. The dial indexes presenting the draincock at the o-ring installation station. An o-ring is removed from the pick up nest and installed onto the draincock. The dial indexes presenting the assembly in front of a vision system. The vision system confirms that an o-ring has been installed onto the draincock. The dial indexes presenting the assembly at the unload station. An automatic good / reject part gating system diverts parts to their respective output chutes. Good parts exit the system via the good parts output chute. Reject parts are diverted to the reject parts output chute and are stored in rejects container below. This system automatically installs o-rings at a rate of approximately 30 parts per minute.

Please CLICK HERE to view a system video.

_______________________________________________________________________________________

CDS MANUFACTURING RECEIVES AN ORDER FOR A TUBE BENDING FIXTURE.

CDS Manufacturing has been awarded a purchase order Bernzomatic to provide a Tube Bending Fixture. This system will bend burner tubes in two different configurations using adjustable and changeover tooling. The operator loads tubes into the fixture and presses a pair of electronic finger buttons to start the cycle. The hydraulic cylinder advances pressing the tube against the form tooling to create the desired tube bend. The operator removes the completed part from the fixture.

_______________________________________________________________________________________

CDS MANUFACTURING RECEIVES AN ORDER FOR A TABLE TOP ROLL SORTER.

CDS Manufacturing has been awarded a purchase order from Vishay Dale Electronics to provide a precision table top roll sorter. This system will include a pair of 12″ case hardened stainless steel rollers with a roller accuracy of +/- .0002″, roller position adjustments, roller position locks, adjustable fallout baffles, and five stainless steel storage bins.

_______________________________________________________________________________________

CDS MANUFACTURING RECEIVES ORDER FOR A SEMIAUTOMATIC DRILLING FIXTURE

CDS Manufacturing has been awarded an order for aSemiautomatic Drilling Fixture

semiautomatic drilling fixture. The operator loads molded

plastic parts into the custom tooled part nest and closes

the safety doors. With a press of a button on the controls

panel, the drill tooling cycles and retracts, drilling the

specified holes the the proper depth. The operator opens

the safety enclosure and removes the completed part.

_______________________________________________________________________________________

CDS MANUFACTURING RECEIVES AUTOMATIC LENGTH SORTING CONTRACT FOR ANOTHER 150,000 WIRES.

CDS Manufacturing has been awarded an ongoing contract to automatically inspect approximately 150,000 medical wires per month for overall length. These parts will be sorted using automatic length inspection machines currently on our production floor. The system, equipped with an LED length inspection station, will automatically inspect .015″ diameter wires for a length of .140″ +/- .002″.

_______________________________________________________________________________________

CDS MANUFACTURING AWARDED CONTRACT FOR VISION INSPECTION OF ONE MILLION RUBBER BUMPERS.

CDS Manufacturing has been awarded a contract to inspect one million rubber bumpers for length and width. Automatic vision inspection equipment, currently on our production floor will be used to sort these parts. Parts will be automatically fed and oriented to a point in front of the vision system camera where they will the length and width of the parts will be inspected. A good / reject gating system will automatically separate acceptable and reject product. Good parts will be returned in the containers that they are received in. Reject product will be returned in separate containers, clearly labeled as “rejects”

_______________________________________________________________________________________

CDS MANUFACTURING AWARDED PACKAGING CONTRACT FOR 10,000 TOILETRY KITS.

CDS Manufacturing has been awarded a contract to collate and package 10,000 toiletry kits. Our production staff will install various soaps, shampoos, lotions, and the like into a labeled zipper bags. Completed kits will be packed out to a specific quantity in an overpack container and stacked on a pallet in the required matrix. The completed pallets of product will be wrapped, strapped and labeled for drop shipping to our customer’s specified location.

_______________________________________________________________________________________

CDS MANUFACTURING AWARDED CONTRACT TO INSPECT ONE MILLIION BRASS INSERTS FOR MISSING THREADS AND CHIPS IN THE INNER DIAMETER

CDS Manufacturing has been awarded a contract to inspect one million brass inserts for missing threads and chips in the inner diameter. Automatic vision inspection equipment, currently on our production floor will be used to sort these parts. A good / reject gating system will automatically separate acceptable and reject product. Good parts will be returned in the containers that they are received in. Reject product will be returned in separate containers, clearly labeled as “rejects”

_______________________________________________________________________________________

CDS MANUFACTURING AWARDED CONTRACT TO AUTOMATICALLY SORT TUNGSTEN PINS BY DIAMETER.

CDS Manufacturing has been awarded a contract to automatically inspect tungsten pins for diameter. The pins will be sorted using automatic diameter inspection equipment currently on our production floor. Parts are fed to an LED measurement system where a single point measurement of the diameter will be taken. A good / reject gating system will automatically separate acceptable and reject product. Good parts will be returned in the containers that they are received in. Reject product will be returned in separate containers, clearly labeled as “rejects”

_______________________________________________________________________________________

CDS MANUFACTURING AWARDED CONTRACT SEMIAUTOMATIC O-RING & RETAINER RING INSTALLATION SYSTEM.

CDS Manufacturing has been awarded a contract to design and build a semiautomatic o-ring and retainer ring installation system. This system will include support and clamping for the radiator tank that the rings are installed onto, staging nests for both rings, part present sensing of all of the components, o-ring / retainer ring vacuum transfer, and vision based inspection of the completed assembly. Acceptable assemblies will be marked with a prick punch.

_______________________________________________________________________________________

CDS MANUFACTURING AWARDED CONTRACT FOR SECOND SEMIAUTOMATIC WIRE DIAMETER INSPECTION SYSTEM.

CDS Manufacturing has been awarded a contract to build a second semiautomatic wire diameter inspection machine.

The operator loads “feedback wires” into the measurement fixture as each is fabricated. The measurement system then moves the wire through an LED / camera measurement head, measuring at several points along the length of the wires. The system records diameters, position, and length. Linear regression is used to characterize the tapered feature of the wires.

The recorded and calculated measurements are used to characterize the natural frequency,

and dimensional accuracy of each wire. This information is then displayed and logged for each individual wire. The operator uses the information to adjust the fabrication operation of the next wire.

_______________________________________________________________________________________

CDS MANUFACTURING COMPLETES SEMIAUTOMATIC GUIDE ASSEMBLY FIXTURE.

CDS Manufacturing has completed the design and build of an automatic guide assembly fixture. This two sided fixture allows one or two operators to assemble product. This operator loaded system confirms the presence of four different components in the assembly fixture. The operator presses a pair of palm buttons and the components are automatically installed. Part present sensors confirm proper installation of the components. An operator interface displays the status of the assembly and alerts the operator to any issues with the assembly.

_______________________________________________________________________________________

CDS MANUFACTURING RECEIVES AUTOMATIC LENGTH SORTING CONTRACT.

CDS Manufacturing has been awarded a contract to automatically inspect medical wires for overall length. These parts will be sorted on one of our automatic length inspection machines currently on our production floor. The system, equipped with an LED length inspection station, will automatically inspect .015″ diameter wires for a length of .140″ +/- .002″.

_______________________________________________________________________________________

CDS MANUFACTURING AWARDED AUTOMATIC DIAMETER INSPECTION SERVICES CONTRACT.

CDS Manufacturing has been awarded an automatic inspection service contract to inspect tungsten wire diameter. Parts will be sorted using one of the automatic LED diameter inspection systems currently on our production floor. Typically, parts are loaded into a vibratory feeder and fed past LED inspection equipment that measures the diameter of the parts. Good and reject product are separated by an automatic gating system. Good parts will be packed out in like quantities in the customer’s packaging. Reject parts will be returned in separate packaging clearly labelled as “Rejects”.

_______________________________________________________________________________________

CDS MANUFACTURING COMPLETES SEMIAUTOMATIC WIRE DIAMETER INSPECTION SYSTEM.

CDS Manufacturing designed and built this semiautomatic wire diameter inspection machine.

The operator loads “feedback wires” into the measurement fixture as each is fabricated. The measurement system then moves the wire through an LED / camera measurement head, measuring at several points along the length of the wires. The system records diameters, position, and length. Linear regression is used to characterize the tapered feature of the wires.

The recorded and calculated measurements are used to characterize the natural frequency, and dimensional accuracy of each wire. This information is then displayed and logged for each individual wire. The operator uses the information to adjust the fabrication operation of the next wire.

_______________________________________________________________________________________

CDS MANUFACTURING COMPLETES SEMIAUTOMATIC VISION INSPECTION SYSTEM.

CDS Manufacturing designed and built this operator loaded vision inspection machine.

This system verifies that the operator has assembled the chain glide face to the chain guide arm properly.

The visiion system looks at both ends of the brackets as they slide through the inspection camera’s field of view. The vision system verifies that both locking features, one at either end, are fully engaged. If they are, a discrete punch mark is applied to each assembly. The inspected parts are automatically ejected from the system into either a good or reject output chute.

Each part is inspected in about 7 seconds.

_______________________________________________________________________________________

CDS MANUFACTURING COMPLETES SEMIAUTOMATIC ASSEMBLY SYSTEM.

CDS Manufacturing designed and built this semi-automatic assembly system.

This system allows two assemblies to be processed at the same time by one or two operators. The operator(s) load one insert and one bracket on to each nest and then begin the machine cycle with the corresponding touch buttons. Part present sensors confirm that the components are all present and thenthe parts are automatically assembled. A discrete punch mark is applied to each assembly for traceability. Completed assemblies exit the system to the rear of the machine.

_______________________________________________________________________________________

CDS MANUFACTURING COMPLETES KNIFE HANDLE FEEDER SYSTEM EQUIPPED WITH VISION INSPECTION EQUIPMENT.

CDS Manufacturing designed and built this automatic knife handle feeder system.

This system utilizes vision inspection equipment and a rotator to orient the handles for blade insertion. A dual headed pick and place positions a pair of handles at the end of the system where the blades are inserted. Part present sensors verify that all of the components are properly positioned and a heating elament assembles the blades to the handles.

KNIFE HANDLE FEEDER

_______________________________________________________________________________________

CDS MANUFACTURING COMPLETES A STEP FEEDER SYSTEM EQUIPPED WITH VISION INSPECTION EQUIPMENT.

A video of a step feeder system is available online, click here…

The system shown here includes a step feeder, output conveyor, vision system, good / reject gating, and process controls for four different parts. Parts in the wrong orientation are diverted back into the step feeder. Mixed parts are gated as rejects, and good parts are fed off the end of the output conveyor. This system feeds parts at a rate of up to 80 parts per minute.

CDS Manufacturing’s Step Feeders offer low maintenance vibration free parts feeding with the ability to feed a wide variety of parts.

In a word….. Simple Reliability.

Contact us for more info…

CDS Manufacturing

1133 Mount Read Blvd

Rochester, NY 14606

585-254-0050

cdsmfg@netacc.net

CDS Manufacturing Step Feeder

_______________________________________________________________________________________

CDS MANUFACTURING COMPLETES ANOTHER O-RING INSTALLATION MACHINE.

A video of an o-ring installation system is available online, click here….

O-RING INSTALLATION MACHINE VIDEO

The system shown in the video includes an infeed conveyor, o-ring magazine and presentation tooling, an o-ring expander, a dual headed pick and place system, o-ring assembly inspection equipment, a touch screen operator interface, good / reject part gating, and process controls. This system installs o-rings at a rate of 20 parts per minute.

Plastic parts are received directly from the mold to the infeed conveyor. Orientation tooling maintains the orientation of the plastic part as it is fed towards the assembly area. Hold & release tooling delivers one part at time to the assembly nest. The assembly nest automatically orients the part radially. O-rings are dispensed from a magazine for removal by the pick and place. The three headed pick & place unit delivers an o-ring to the expander, installs an o-ring, and removes the prior assembly simultaenously. Completed assemblies are inspected for proper o-ring installation. Good & reject parts are gated accordingly and exit the system via their respective output chutes.

Automatic and semiautomatic o-ring installation machines are available for a variety of assembly operations. O-ring assembly systems are available with individual parts feeders, magazine fed o-rings, assembly inspection equipment, and more.

Contact with your o-ring assembly application for a free quotation.

CDS Manufacturing

1133 Mount Read Blvd

Rochester, NY 14606

585-254-0050

cdsmfg@netacc.net

_______________________________________________________________________________________

CDS, Inc. Buys Assets of Lipe Automation

Contract Design Service, Inc. has acquired product line assets of Lipe Automation in Liverpool, NY including the Dyna-Slide and Dyna-Belt brand names, and additional parts feeding, conveyor, and material handling products. “CDS LIPE Manufacturing” designs and builds a full range of material handling equipment.

Contract Design Service, Inc. is also the parent company of CDS Manufacturing in Rochester, NY. CDS Manufacturing designs and builds automation equipment, inspection and sorting systems, vibratory feeders and step feeders, and provides inspection, sorting, packaging, and assembly services. Increased business volumes and planned acquisitions are adding to the corporations future growth.

Please feel free to contact us for a free consultation regarding your application at either our Rochester, NY or Liverpool, NY locations.

CDS LIPE

Division of Contract Design Service, Inc.

290 Elwood-Davis Road, Liverpool, NY 13088

Ph: (315) 457-1052

Fax: (315) 457-1678

http://www.cds-lipe.com/

sales@cds-lipe.com

CDS Manufacturing

Division of Contract Design Service, Inc.

1133 Mount Read Blvd

Rochester, NY 14606

Ph: (585) 254-0050

Fax: (585) 254-0711

cdsmfg@netacc.net

_______________________________________________________________________________________

CDS Manufacturing completed an automatic system that inspects worm gear shafts for journal diameter and inspects for the presence of chips wrapped around both ends. Parts we fed from a vibratory bowl feeder to a gravity track with the parts oriented end to end with the short end leading. A hold and release mechanism allowed one part at a time into an inspection nest where an LED inspection system measured the journal diameter. Upon completion of the journal diameter inspection, a vision system, with the aid of back lighting, inspected the part for chips wrapped around either end of the part. A good / reject part gating system was provided to separate the parts. Parts found to have a journal diameter that did not fall within the specified limits were gated as rejects. Parts that passed the LED and vision inspection were gated as good parts and exited the system via the output chute provided.

_______________________________________________________________________________________

CDS Manufacturing completed an order for a 5 up spheroid sorter. The system automatically inspects spherical product for flats, doubles, clusters, and debris. Parts are fed from a common hopper to a vibratory surface that separates the spheres according to their individual quality. Parts are sorted at an estimated rate of over 200,000 parts per minute. Sorted parts are stored in common storage bins.

_______________________________________________________________________________________

CDS Manufacturing received an order for a Precision Roll Sorter equipped with 50 millionths TIR rollers. System included a bulk hopper, linear vibratory feeder system, orientation station, output track, precision rollers, roller adjustments and locks, adjustable baffles, roller speed controls, and stainless steel storage bins. The entire system was mounted on a heavy duty machine base. System will be used for sorting of screw machine parts for length, width, diameter, and foreign materials.

_______________________________________________________________________________________

CDS Manufacturing received an order from a screw machine parts manufacturer for inspection services to inspect a wide variety of screw machine parts. Inspection services include oversized inner diameter inspection, missing thread inspection, inspection for chips and foreign materials, length inspection, and outside diameter inspection. Automatic inspection services are provided by modifying in house inspection equipment to perform various inspection tasks such including laser inspection services, vision inspection services, eddy current inspection services, LED inspection services, roll sorting services, and custom automated inspection services. CDS Manufacturing also provides manual inspection services.

_______________________________________________________________________________________

CDS Manufacturing has completed building a machine to inspect automotive Fuel Pressure Connector Bodies. The fully automatic system uses a vibratory bowl feeder and Eddy Current technology to sort out defects including cracked parts, undersized threads, missing threads, deformed features, long parts, short parts, bar ends, material defects, chamfer deviations, and soft parts. Good parts are fed via a cleated conveyor to an automatic tote handling unit for packout.

_______________________________________________________________________________________

CDS Manufacturing has completed the design and build of a Radiator Inlet and Outlet Tank Assembly System. The automatic assembly system automatically installs a petcock, installs clamp nuts, confirms o-ring presence, and spin-welds a closure plug in place. The system included error proof fixturing (poke-yoke) and included part present sensors and tooling to confirm proper assembly.

_______________________________________________________________________________________

CDS Manufacturing received an order to length sort pistons for parts with an undersized length. A roll sorter, currently on our production floor, was modified and equipped with a laser and gating system to sort the parts for undersized length.

_______________________________________________________________________________________

CDS Manufacturing recieved an 80,000 piece kit building order for packaging of automotive components. Six accessories are packaged in a heat sealed bag. The automotive component is wrapped with bubble wrap and inserted into a box with the heat sealed bag of accessories. Box labels and pallet labels are applied. To date, and for the past 23 years, CDS Manufacturing maintains a zero defects record with this customer.

_______________________________________________________________________________________

CDS Manufacturing received an order to inspect automotive manifolds. Twenty five different features are inspected on each part, including visual inspection for flash, damage and missing components, as well as gauging, fit and functional testing.

_______________________________________________________________________________________

CDS Manufacturing received an order to inspect valve assemblies. The application called for us to sort for oversized diameter of a hole in the valve, and the visual inspection of the assembly to confirm the presence of two O-rings.

_______________________________________________________________________________________

CDS Manufacturing received a containment order to inspect automotive electrical connectors for poorly assembled components. The nationally known electronics company was referred to us by the end user who happens to be one of our long time automotive equipment customers. The containment was completed within four hours.

_______________________________________________________________________________________

CDS Manufacturing received an order for contract sorting of a family of dowel pins. The requirement was two fold. Inspect dowel pins for a specified diameter with a tolerance of +/- 0.00025”, and sort for length to a tolerance of +/- 0.005. To accomplish the diameter sort, we utilized an existing Roll Sorter (also known as a roller sorter) on our production floor. Our precision Roll Sorters are capable of sorting to within 0.000050”. That’s 50 MILLIONTHS of an inch! For the length sorting requirement we utilized a vibratory parts feeder and linear vector displacement transducer (LVDT) currently on our production floor. The parts are automatically fed to the LVDT measurement tooling where we sort for length. Good parts and reject parts are sorted into separate storage bins by an automatic gating system.

_______________________________________________________________________________________

CDS Manufacturing received an order for contract inspection and sorting of two similar parts that were mixed at the plating process. The parts differ in length by less than .001″. To accomplish this task, we modified an existing laser sorting system on our production floor. The system utilizes a vibratory parts feeder to feed, orient, and present the parts to the laser measurement tooling. The automatic system sorts mixed parts at a rate of 2,500 parts per hour.